SY-NUT for locking bolts and nuts

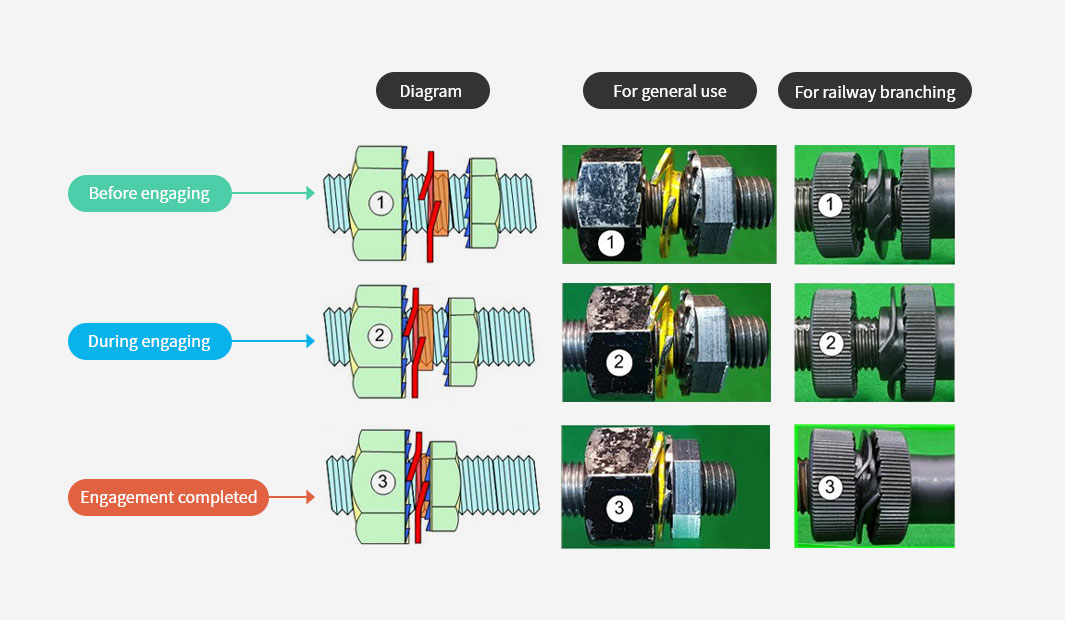

Principle of SY-NUT(Tightening of Bolts & Nuts)

SY-NUT is most suitable for fastening structures under vibrations.

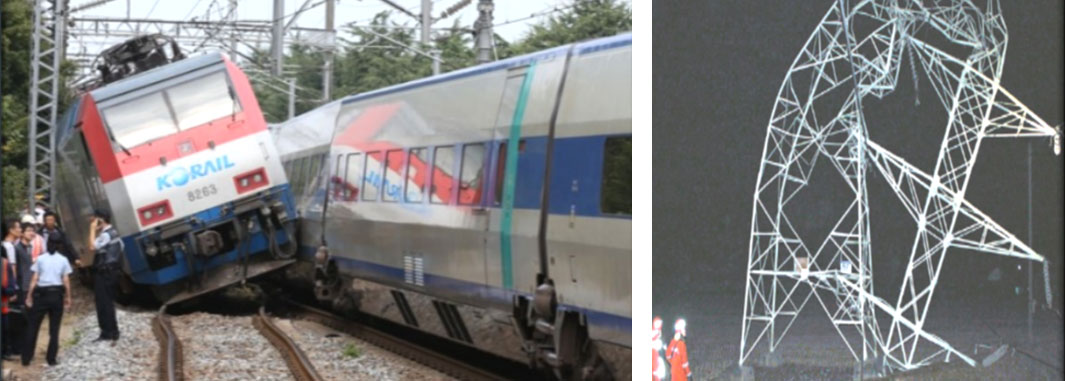

SY-NUT(Flexibility against Train Derailment and Collapse of pylon)

SY-NUT guarantee bolts and nuts to be sale and locking engagement from au structures under vibrations and shock in the following fields

– The engagement of railway rails

– Locomotives

– Beams of the transmission line(Pylon) bridge deck

– Beams of construction structure

– Various heavy machinery (military tanks, automobiles and planes), etc.

(Left) The train derailed due to loosening of bolt and nut at the track branch. / (Right) The transmission tower that could not withstand a typhoon.

These are “the problems of flexibility”

SY-NUT(Prevention of bolts & nuts Loosening under Vibration and Shock of Structures)

Bolts and nuts are essential components for tightening structures, but they have structural problems that by vibration and shock. SY-NUT (Bolts and Nuts that prevent loosening) solves this phenomenon fundamentally.

The various methods to prevent bolts & nuts loosening

SY-NUT(Free tightening; Loose tightening is also possible) OK

The feature of SY-NUT is to maintain the tightening condition without releasing, even if it is moderately tightened at any tightening end point.

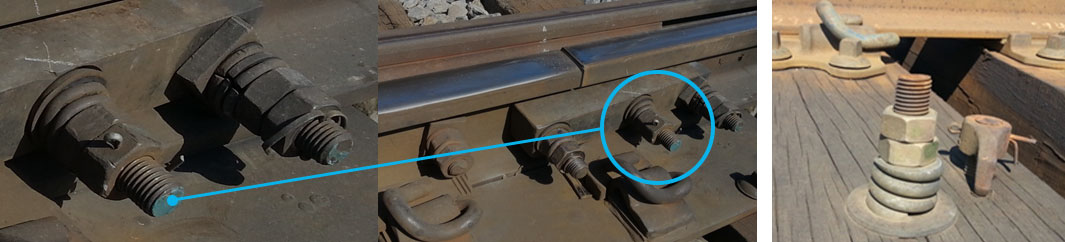

- Concrete sleeper that ruptured on railway tracks

When fastening different materials, for example, concrete sleeper and rails, Excessive tightening can pose a risk to train safety due to concrete rupture, and loose tightening will not ensure the safety of the train due to incomplete fastening.

- The joint region of excavator : Excessive tightening will inhibit rotation and loose tightening is unsafe and dangerous.

- Screws will not loosen even if moderately tightened at any point.

The Excellence of SY-NUT Technology

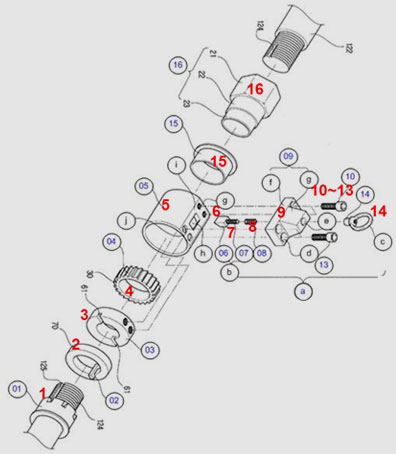

- Existing methods to prevent loosening

– To fasten several nuts

– To insert split pins by drilling holes in the bolts and nuts

– To fill the space between the screw nuts with ring-shaped coils - This SY-NUT product is normally rotated in the screw tightening direction so that it can be tightened.

However, it prevents loosening by making it impossible to rotate due to a latch at ordinary time. - During the maintenance, bolts and nuts can be loosened by pressing the latch with a box wrench.

- Even if properly or loosely tightened, it will never be released in the opposite direction.

- Existing nuts have many difficulties.

– They cannot be used for long term due to corrosion(oxidation) of metals caused by the water ingress such as rain.

– They can be also damaged during the inspection of dismantling. - This SY-NUT product can use nonmetallic stainless steel or alloy, and can prevent corrosion by applying lubricant(grease) to effectively block oxygen and moisture.

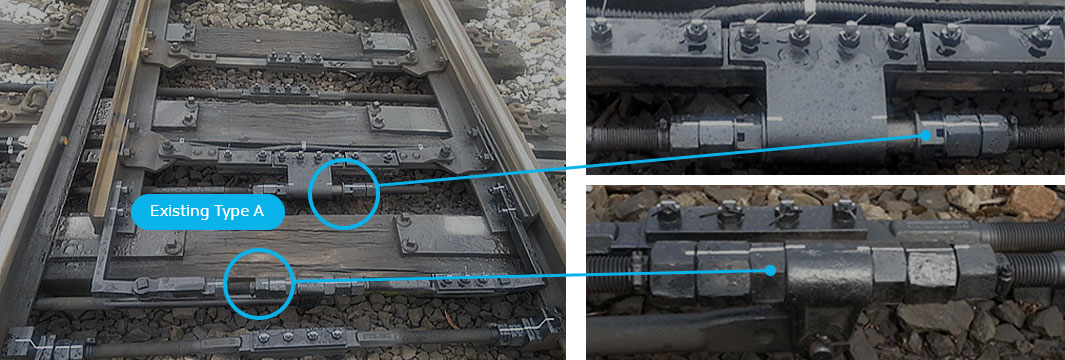

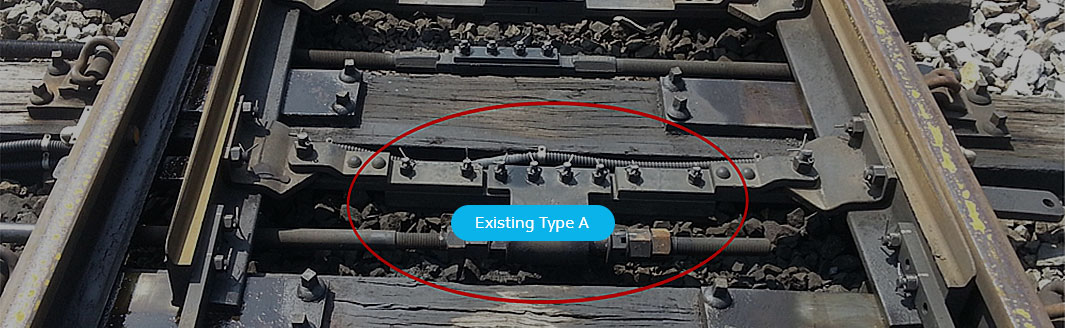

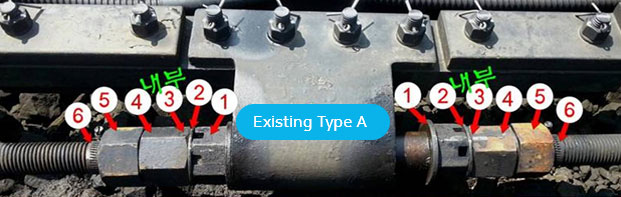

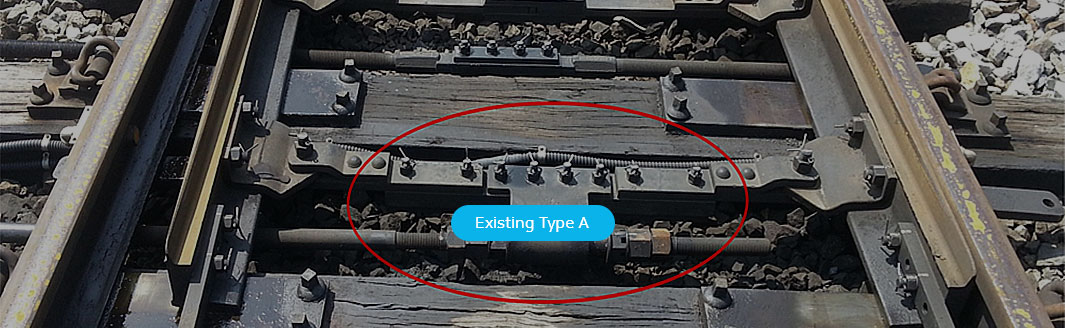

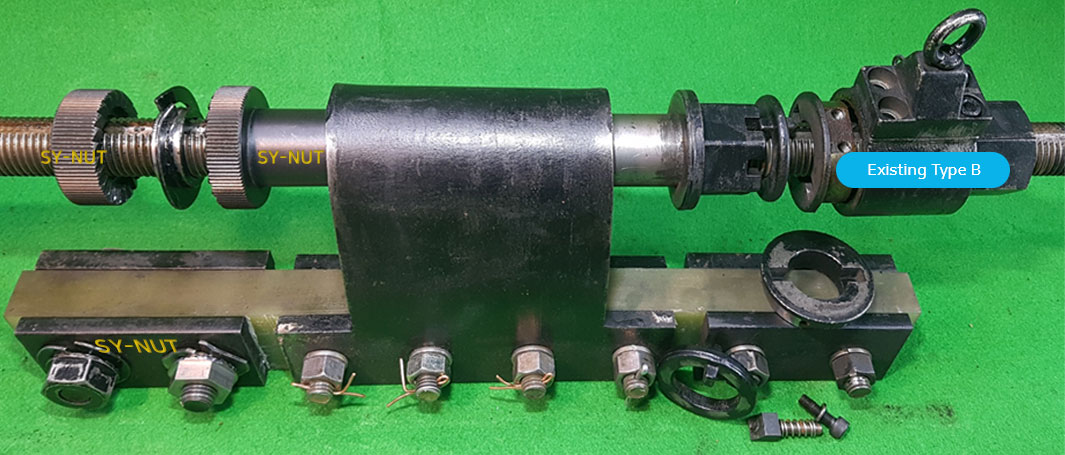

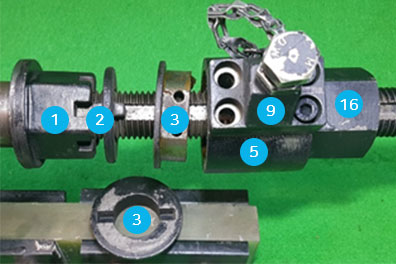

Comparison SY-NUT with Existing Type A

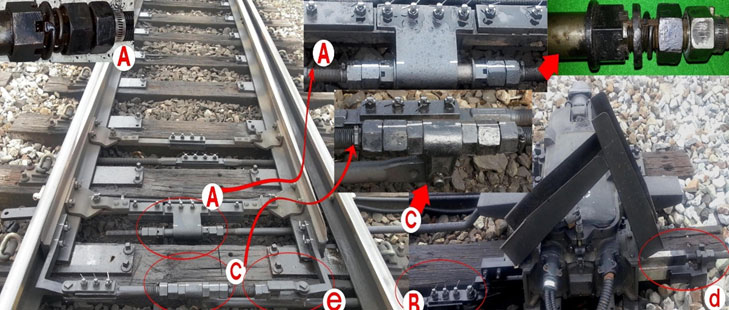

main(operation) switching point at the railway track switchboard : SY-NUT 3ea / main(operation) switching point at the railway track switchboard : Before 6ea

Comparison SY-NUT with Existing Type B

Photo of the main (movement) switching part of the railway line changer

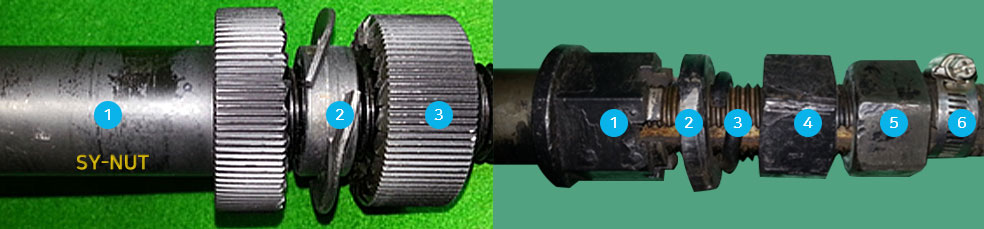

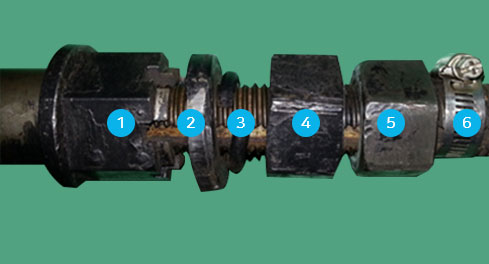

Comparison of existing nuts

Existing nuts require a lot of parts to prevent the release from vibration of trains as a key component of the on-site railway track switchboard.

Existing Type B

Existing Type A

SY-NUT

It is a structure that the key-washer is caught between the saw tooth formed on the left and right nuts, so it cannot be loosed without the artificial release by the tool.

Comparison Table of Similar nuts

| SY-NUT | B Company | C Company | D Company | |

|---|---|---|---|---|

| Image |  |

|

|

|

| Principle | Built-in Key Washer (Stainless steel and Alloy) | Material : Plastic | Built-in Heli-coil | Bolt drilling, Using split pins |

| Merits and Demerits | Free screw tightening, Lubricant application recommended |

Material deformation due to lubricating oil |

Difficulty in applying lubricant |

Re-drilling bolt on reuse |

Applications of SY-NUT(Heavy equipment for automobiles, Engines of ships)

Heavy equipment for automobiles

SY-NUT guarantee bolts and nuts to be sale and locking engagement from all structures under vibrations and shocks in the following fields

– The engagement of railway rails

– Locomotives

– Beams of the transmission line(Pylon) bridge deck

– Beams of construction structure

– Various heavy machinery (military tanks, automobiles and planes), etc.

Engines of ships

It’s connected INa lot of bolts..

Applications of SY-NUT

A transmission tower junction

Joint points of mechanical equipment

Existing devices of railway at turning point are used in double or triple to prevent loosening.

Before engaging

Engagement Complete

During engaging